Start your testing at the minimum cost of RM950 for the first 24 hours and fairly lower than the others every day.

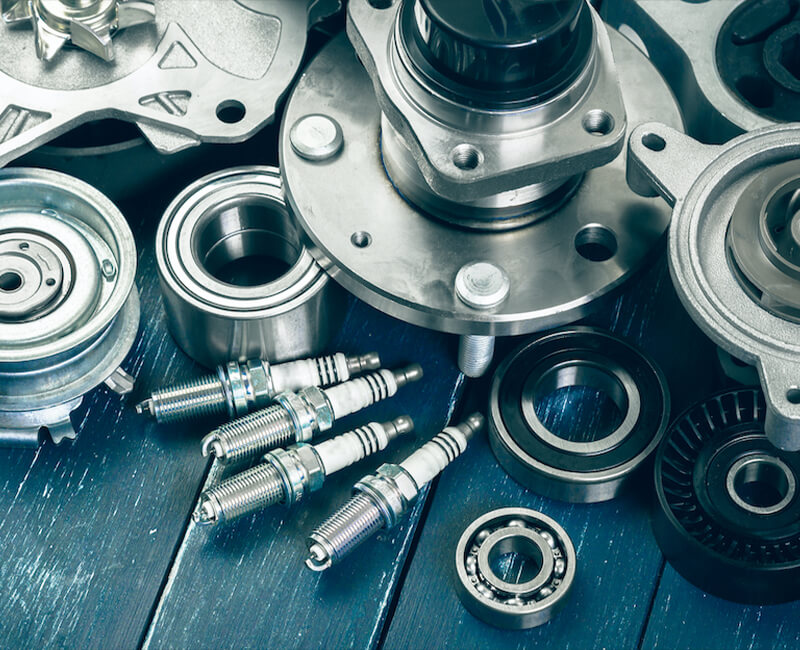

Corrosion Testing determines the resistance of materials to corrosion under certain environmental conditions, including temperature, humidity and saltwater. Since all metals and alloys are susceptible to corrosion, corrosion test results can help businesses make sound decisions. The effects of corrosion can be costly and devastating, so it generally makes sense to perform testing before damage occurs, often during product design.

Corrosion testing is an important step in material selection in order to establish the suitability of materials for their intended use. Corrosion analysis can also help identify a corrodent or an environmental cause if an unexpected corrosion problem occurs. Standardmark Laboratory offers a wide range of corrosion testing in meeting our customer needs.

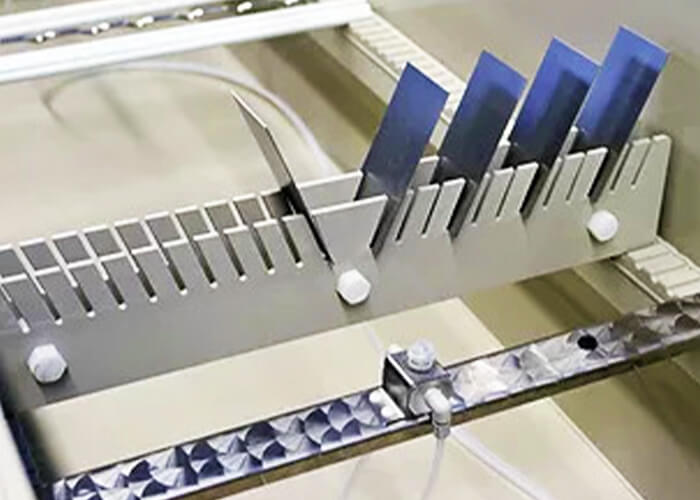

Salt spray testing is relatively inexpensive, well standardise and reasonably repeatable approach. Most of the salt spray testing aims to maintain coating processes such as pre-treatment and painting, electroplating, galvanizing, and the like, on a comparative basis, rather than analysing corrosion resistivity. For example, pre-treated + painted components must pass 96 hours Neutral Salt Spray, to be accepted for production. The testing plays an important role in quality control of production.

There are many compelling reasons why you should carry out the salt spray test but the main reason is to determine how corrosion will affect your specimen. Diverse surfaces and metals can exhibit varying amounts of resistance to corrosion, and this test allows you to compare this. In addition, the test enables you to determine a surface's propensity to corrode in case it is scratched and assess stickiness coating.

There are many examples of relative salt spray test results such as:

There is a limitation of the testing where the testing exposure period is less likely to be correlated to the real-time application.

A product testing laboratory based in Malaysia. Our Laboratory is accredited by the Department of Standard Malaysia according to MS ISO/IEC 17025 and International Laboratory Accreditation Cooperation (ILAC), to ensure our laboratory provides world-class testing services that are worldwide recognized, and accepted by local national authorities or regulators, in order to serve as a key to enter a market.

2022 @ Copyright - Standardmark Laboratory Sdn Bhd